SE300 v1.4 Hotend Variations

SE300: Probing since 2016!

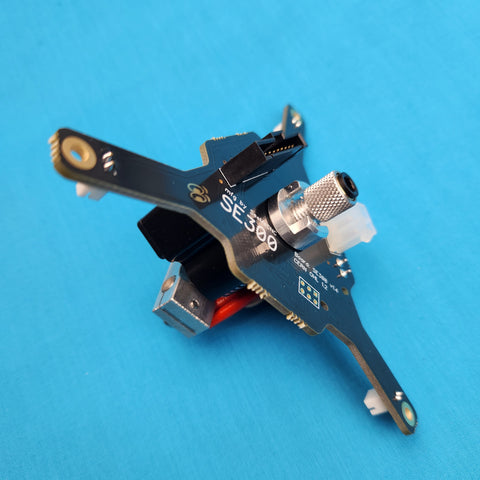

The SE300 hotend is the same hotend used on all BOSSdelta, Artemis, RostockMAX v3.2 and RostockMAX v4 models. No soldering required. The pcb is designed and manufactured in-house at SeeMeCNC!

The on-board micro controller and probing strain gauge circuit are built-in and based on the Duet Smart Effector circuit. Our 4 layer pcb contains two inner layers with squiggly sensor traces used to detect strain when probing. Each board is programmed and tested for functionality. To compare probing, the strain gage probe is three times more sensitive than the HE280 accelerometer probe. More accurate probing, more reliable probing. A bright blue LED clearly indicates probe sensing.

The triple blower design provides exceptional part cooling right where it's needed! Make incredible no-support bridges and improve print quality while reducing clean up post print processing.

Let's not forget about the bones! The industrial grade glass filled nylon frame is heavy duty! The injection molds are made in-house. Then we also injection mold the parts in-house too!

Compatibility:

- BOSSdelta 500

- BOSSdelta 300

- Artemis 300

- RostockMAX v3.2

- RostockMAX v4

Designed for use with DUET control boards.

Fully Assembled Includes:

- 300 size SE300 Hotends (300mm dia bed)

- Include 0.5mm diameter brass nozzle standard

- Single or Dual Extrusion

- Metal or Plastic Ball Joints

- 500 size SE300 Hotends (500mm dia bed)

- Include 0.7mm diameter brass nozzle standard

- Single or Dual Extrusion

- Metal Ball Joints

* Whip and mating connectors are not included.

Other parts required if upgrading from a previous version

- instructions here

- Updated Whip - Compatible with SE300 v1.4.

- Whip Upgrade to v1.4 Kit - Modify your existing v1.3 whip to work with SE300 v1.4.

Made in the U.S.A.